Interdisciplinary collaboration between different technical departments is crucial in the development and manufacture of high-quality optical precision components. For example, it is just as essential to take tool requirements into consideration as early as the lighting development stage as it is to take lighting requirements into account during tool design and tool construction.

We design and construct tools and perform preventative tool maintenance in-house and with trusted partners. Experienced teams of in-house specialists in tool design and construction, short routes to product development, production and all other technical expert groups, and not least our shared practical experience developed over the course of many years and projects enable us to create tools with the most sophisticated inject-moulding components. This allows us to react quickly and flexibly – even while production is ongoing.

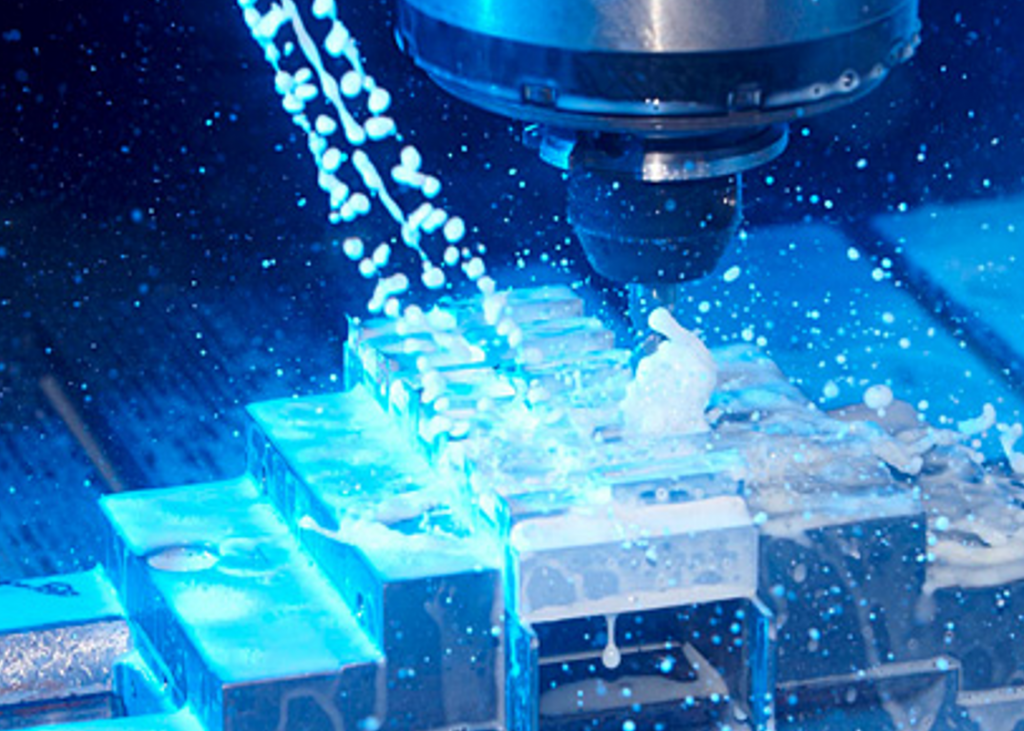

Fully equipped tool construction departments at our Erkrath and Pforzheim sites mean we can – completely independently – produce multi-component injection tools and equipment for manufacturing technically complex plastic parts and optical components. We use Ingersoll 5-axis simultaneous milling machines, DMG CNC processing centres and state-of-the-art vertical eroding and wire-cutting technology from Ingersoll and Mitsubishi.