They are tiny, bright and long-life, UV and IR-free, energy-efficient, shock-proof and maintenance-free: light-emitting diodes – or LEDs for short. They have a huge number of benefits and are the light source of choice here at MENTOR. There is an almost endless choice of LED types, models, sizes, beam angles and lighting and performance variants. However, they differ in terms of their life and other quality features, certifications and approvals, their long-term availability and, not least, in terms of their price. As a result, there is an enormous range with a wide variety of options for developing modern lighting solutions.

LEDs – the source of our lighting

At MENTOR, we do not develop or manufacture our own LEDs. However, we have been using LEDs successfully in our opto-electronic components and customised lighting solutions for more than 40 years. During that time, we have closely followed the development and trends of LED technology and have used it in many different ways. Our decades of experience with this light source, our extensive market and technology know-how and our years of close collaboration with leading LED manufacturers mean we are in a position today to make the best possible use of this innovative light technology for our customers.

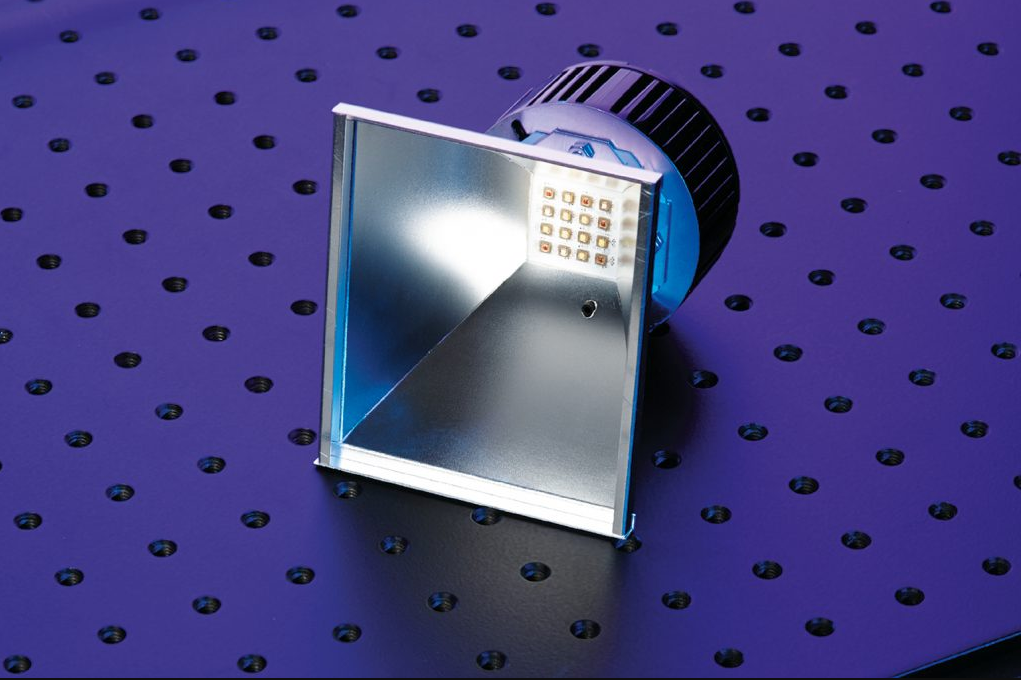

Our specialists in product development and our expert lighting development department use state-of-the-art development and simulation tools in our own lighting laboratory to develop the very best solutions, to predict the desired lighting results in advance by using simulation and to validate the results achieved.

Does LED technology have a downside? Of course – wherever there is light, there is shadow too. Even though the benefits of LED technology clearly outweigh the downsides, the disadvantages are significant: at excessively high temperatures, LEDs age prematurely, reducing their life substantially. As LEDs age, whether through a natural process or prematurely due to excess temperatures, their colour location and brightness changes, which is clearly visible to the human eye. The same unwanted effects occur irrespective of an LED’s age if it is used at greatly fluctuating temperatures. And a third phenomenon is worth noting: the colour location and brightness of an LED can fluctuate within a bin depending on production factors.

We are fully aware of these disadvantages and meet the associated challenges by applying different strategies for different applications: in the simplest case, by selecting suitable high-quality LEDs, in many cases by developing and integrating suitable thermal management and for the most challenging scenarios, by using microprocessor-controlled LED modules and individual end-of-line LED calibration.

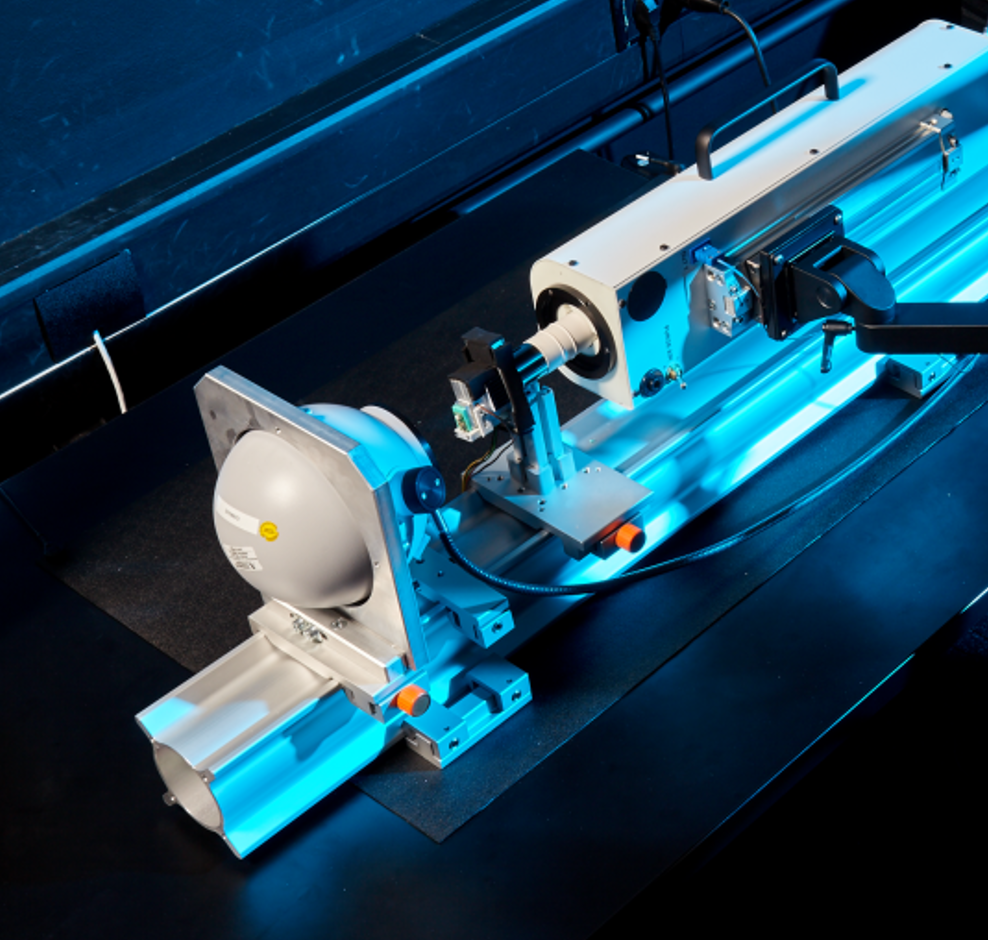

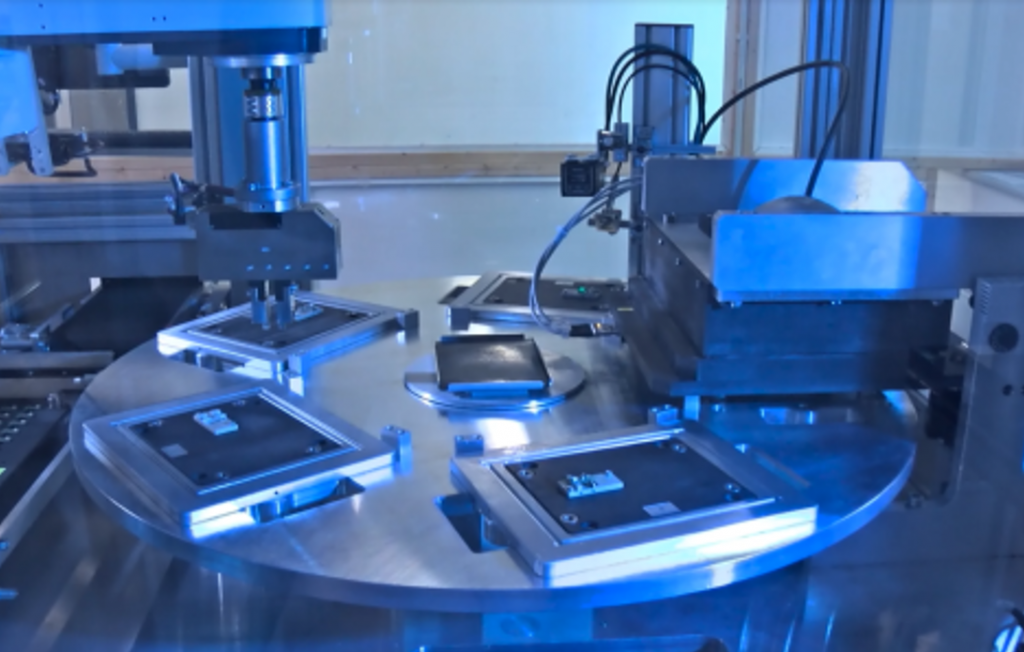

Under the leadership of a dedicated department in our electronics division, and with the help of specialist development partners where necessary, we develop series production-ready control electronics, for example for control protocols such as Zigbee, DALI, LIN, DMX or KNX, in accordance with customer requirements. Another specialist electronics department is responsible for hardware and software development for (opto-)electronic test stands and database-based end-of-line testing systems. Scientifically precise measurement of our LED lighting solutions is a necessity here in order to guarantee consistent quality. We define our measurement methods and measurement variables in close consultation with our quality assurance department.

RGB coloured lighting solutions

If a customer requires changeable coloured light, or if coloured light is to be adjusted individually or is to change in different situations through sensor controls, RGB or RGBW coloured LEDs are used as a rule. Elaborate multi-coloured solutions and dynamic light scenarios are practically inconceivable without them. RGB lighting solutions are particularly complex when multiple RGB LEDs have to be coordinated with each other in one application, so that a constant colour location and identical brightness of all RGB lights integrated in the system is guaranteed. The human eye can pick up on even slight differences in colour and brightness: the lighting result is perceived to be uneven and of poor quality. Therefore customers want lighting solutions that produce a homogeneous colour pattern, where all RGB light sources are perfectly synchronised.

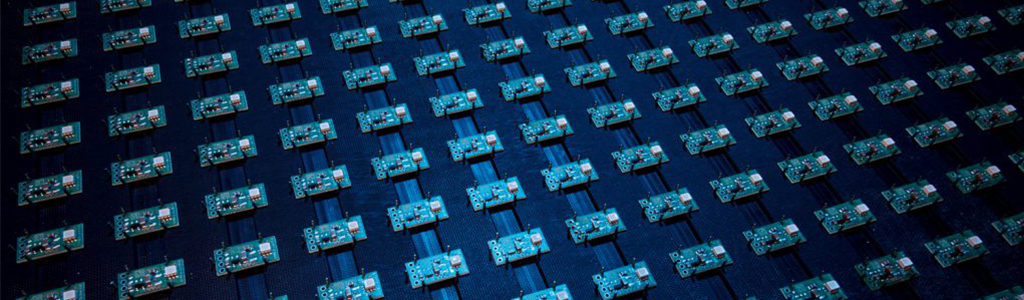

For complex coloured lighting applications such as these, we have developed an RGB LED solution with an integrated microcontroller. The microcontroller and the one hundred percent end-of-line module calibration make it possible to compensate for temperature and ageing-related effects as well as production-based colour and brightness bins. At the same time, the light flow from each module is individually adjusted in order to avoid light density differences between individual applications, or to make deliberate use of them.

Light mixing in the RGB colour light module

An integrated mixing lens in the RGB coloured light module ensures good colour mixing of the individual RGB LED chips and thus a consistent colour impression over the entire length of the light application.

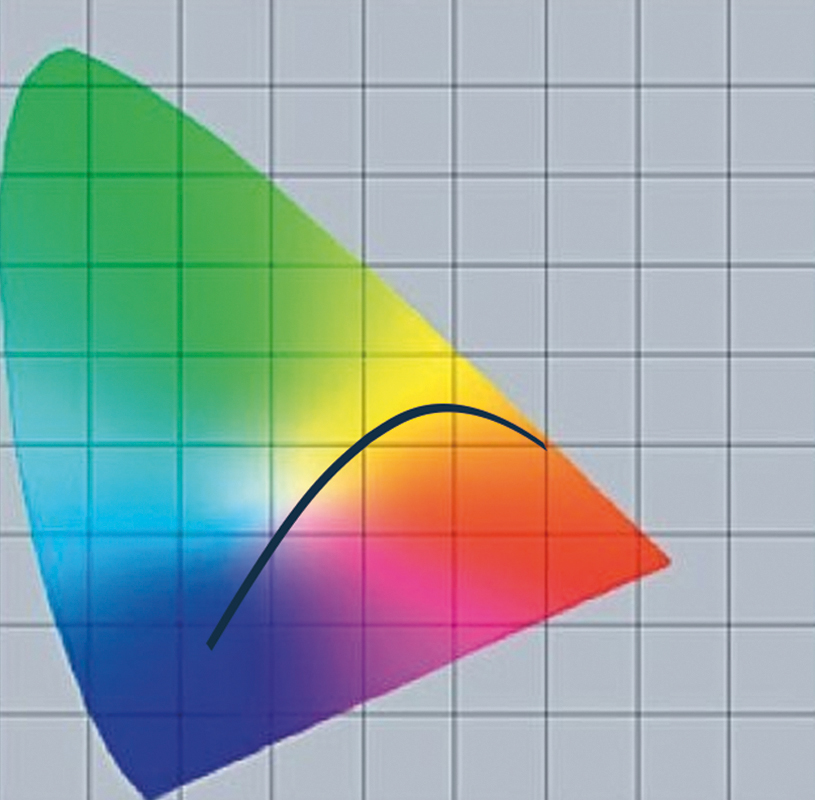

Tunable white

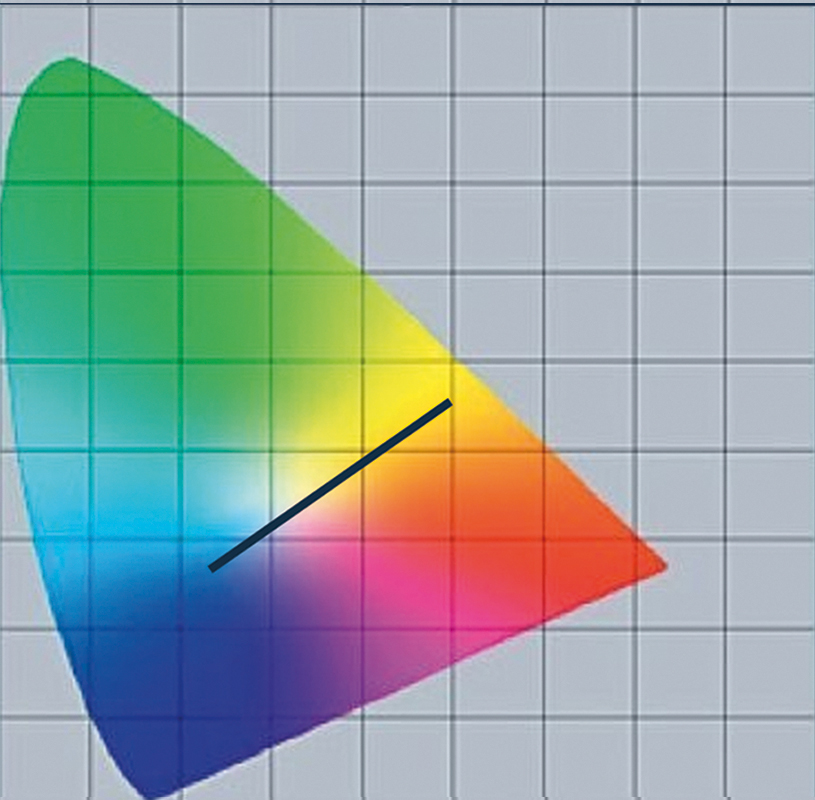

The ability to dynamically control the colour temperature in the white light range using high-performance LEDs has many advantages. By adjusting the colour temperature, white lighting can be adjusted perfectly for the object to be lit or to suit the desired mood. Automatic colour temperature control along the Planck curve in a defined time period even allows light to be adjusted precisely according to changes in daylight. These solutions are used particularly in human-centric, circadian and biodynamic lighting. However, if a perfectly synchronised light temperature in several lights is the order of the day for aesthetic reasons, and light-related temperature or ageing effects need to be compensated for, then Tunable White solutions are the ideal choice.

MENTOR develops and produces LED-based Tunable White applications in line with individual customer requirements with a colour temperature range from 2,500 to 9,900 Kelvin and a colour reproduction quality with very high CRI values. By doing so, we enable our customers to benefit from the potential of this technology without having to expand their own expertise. Cost-effective versions with cool white/warm white LEDs are possible, as well as sophisticated options with blue/mint/amber LEDs and excellent colour location precision.